Learn more about Rhenium Alloys

Request Quote

Careers – Download Application

TF: 888-RHENIUM PH: 440-365-7388 FX: 888-366-9830

Quality Assurance

Inspection Equipment

Rhenium Alloy’s Quality System

will ensure that you receive your product manufactured to your

exact specifications.

Whitepapers and Abstracts

Resources and Downloads

Rhenium Alloys, Inc. consistently researches and develops new applications for its refractory metal products.

Contact Rhenium Alloys

Request Quote

Careers – Download Application

TF: 888-RHENIUM PH: 440-365-7388 FX: 888-366-9830

Industrial Services

Rhenium Alloys has the expertise and equipment to handle many industrial metal services.

Products & Materials

Product Datasheet

Downloads

Industrial Services

Industrial Services

Rhenium Alloys has the expertise and equipment to handle many industrial metal services, including Cold Isostatic Pressing, Heat-Treating (Annealing and Sintering), Swaging, Drawing, Testing Mechanical Properties, Straightening and Flattening, Center-less Grinding, Rolling, and Engraving.

General

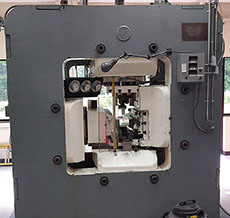

Cold Isostatic Presses (CIP)

Rhenium Alloys has two cold isostatic presses (CIP) 10” ID X 24” deep and 4” ID X 22” deep. Both units are high pressure at a maximum pressure at 60,000 psi.

Cold Isostatic Pressing is a method of compacting powders via hydrostatic pressure.

Cold Isostaic Pressing is used to consolidate metal, to make a “Green Part” that can be further treated. For example, rolled, machined or sintered. CIP pressing offers programmable pressure distribution with good accuracy reduced mechanical stresses of processed material and has superior process control at all pressure levels. One benefit from choosing CIP pressing is the increased mechanical properties.

High Temperature Furnaces for Annealing and Sintering

Rhenium Alloys employs 100% hydrogen atmospheres in all of our heat-treating furnaces. The range of heat treating temperatures is 760°C – 2450°C depending on dimension of the specific parts.

We have both muffle furnaces and precision laboratory furnaces. All furnaces have data log capability as well as ramp programs for specific sintering applications. They are controlled and calibrated with Ircon 5 pyrometers that allow for specific temperature monitoring. Rhenium Alloys can heat treat your refractory metals from 760°C – 2450°C.

Flat Wire Mill Wire / Rod / Tubing

Wire / Rod / Tubing

15 Different Types of Swagers

Swaging is an operation to reduce the diameter of a rod. Rotary swaging (rotary forging) is a hammering operation on the outside diameter of a rod. Rhenium rotary swages from room temperature to 1650°C, from 2” to 0.060” diameter.

Swaging is used for metal forming by reducing the cross section of bars or tubes. Rhenium Alloys offers a wide variety of rotary swagers to accommodate various diameters. Rhenium Alloys has 4 die and 2 die swaging machines that can be used on both cold and hot processes. Rhenium Alloys has over 51 years of swaging experience. We have developed processes for Ruthenium, Nickel based super alloys and various other refractory metals. Rhenium Alloys can process material from .100 to 1.5 inches in diameter. Various dies can be engineered and purchased to go higher or lower. Our swaging department consists of 15 different types of swagers that use both inductions, continues feed and natural gas. We can maintain, data log and create new processes with our extensive knowledge of manufacturing processes.

Drawing Department / Drawing Equipment

Drawing is performed at room or elevated temperature from 1.5” to 0.004” diameter on wire, rod and tubing. Rhenium Alloys will process a wide range of material in the drawing operation.

Rhenium Alloys drawing department consists of the following equipment:

- Caterpillar: This machine is used for heavy area reductions in excess of 45%. Drawing temperatures can reach 1350°C, and wire diameters drawn are from .050 – .250.

- Bull Block: The bull block is used to draw large amounts of materials with one single draft. Drawing temperatures can reach 1100°C, and wire diameters typically drawn are from .030 – .080.

- Side-Wheel Drawing: The side-wheel is a single die capstan for large amounts of wire. Drawing Temperatures range from 400°C to 1000°C, and wire diameters typically drawn are from .020 – .080.

- Multiple Fine Wire Drawing Machines: Rhenium Alloys has 5 and 10 die multi die machines used for drawing wire from .020 to .0015.

Rhenium Alloys uses the MTS Q-Test for testing the mechanical properties of all wires. Specific mechanical properties and hardness can be achieved for your products.

Straightening and Flattening

Straightening and Flattening operations are employed for sheet, foil, wire, rod, and tubing at room and elevated temperature to meet the customer requirements of straightness and flatness.

Center-less Grinding

Rhenium Alloys center-less grinds rods and tubing to very fine finishes and tight tolerances based on diameters and length of the part.

Sheet

Rolling

Rhenium Alloys has the facilities to cold roll and hot roll up to 1650°C plate, sheet and foil to a customer’s required widths and thickness.

Engraving

Boss FM20 Laser Engraver

Rhenium Alloys has purchased a Boss FM20 Laser Engraver. This laser engraver allows for the addition of permanent identification to customer parts – which facilitates long term identification and traceability.

The Boss FM20 Ytterbium 20W laser marker includes Q-switch or a pulsed output laser beam. Ideal for permanently marking and engraving raw metal applications as well as industrial polymers. The improved beam quality, coupled with 10X more focus beam diameter, makes this fiber marker ideal for applications that demand extreme precision.

The Boss FM20 engraver boasts excellent capabilities that support Rhenium Alloys’ needs and customer’s requirements. It has an adjustable Z-axis with a focus height up to 30” and a marking area of 4.33” by 4.33”. This system can support PLT, BMP, DXF, JPG, TIF, AL, PNG, and JPG image formats. The marking system has a variable pulse wave frequency that can be adjusted from 20-80 KHZ. It has a marking accuracy of .002”. Its adjustable open platform allows us to engrave many different shapes, from flat sheet products, wire, and tubing, all the way to bulky objects with extremely awkward shapes.

FEATURES

- Adjustable Z-axis focus height up to 30”

- Fiber marking area up to 110mm by 110mm (4.33” by 4.33”)

- Adjustable open platform

- Up to 100x faster compared to Gantry system lasers

- Open table does no limit size of material

- Pulse Wave Frequency 20-80 KHZ

- Supports PLT, BMP, DXF, JPG, TIF, AL, PNG, and JPG image formats

- Marks at a speed of 5000mm per second

- Laser Wavelength of 1064nm

- Repeated accuracy of .002”

If permanent long-term marking of your RAI products is of interest to you, or if you have your own products that need engraving, please contact our sales staff today.

We would be more than happy to work with you to find the best solution for your product needs.

SERVICED IN USA

All of our industrial metal services are performed at our facility in Northeastern Ohio.

* Some materials and compositions may not be suitable to our processes

Drawing Caterpillar

Bull Block Wire Drawing

Straightener (TAK Cutter)

Center-less Grinder

Centour Furnace

Induction Furnace

1033 Torrington

Hot Working Furnace

Rhenium Alloys' CM Furnace Room

Large Bar Sheet Press

Spectra Mat and Element Heater

Wire Etcher

Boss FM20 Laser Engraver

Website by: Unity Design, Inc. Icon Fonts: Font Awesome

PH: 440-365-7388

FX: 888-366-9830

TF: 888-743-6486

(888-RHENIUM)