Learn more about Rhenium Alloys

Request Quote

Careers – Download Application

TF: 888-RHENIUM PH: 440-365-7388 FX: 888-366-9830

Quality Assurance

Inspection Equipment

Rhenium Alloy’s Quality System

will ensure that you receive your product manufactured to your

exact specifications.

Whitepapers and Abstracts

Resources and Downloads

Rhenium Alloys, Inc. consistently researches and develops new applications for its refractory metal products.

Contact Rhenium Alloys

Request Quote

Careers – Download Application

TF: 888-RHENIUM PH: 440-365-7388 FX: 888-366-9830

Industrial Services

Rhenium Alloys has the expertise and equipment to handle many industrial metal services.

Products & Materials

Rhenium MOCVD Heater Filaments

For nearly 20 years Rhenium Alloys has been the leader in production of the highest quality rhenium heater filaments for the MOCVD Industry. Rhenium Alloys has been the OEM for many of the world’s most reputable and respected MOCVD equipment manufacturers, along with being the specialty filament supplier for the most revolutionary and technology leading LED companies in the world.

For nearly 20 years Rhenium Alloys has been the leader in production of the highest quality rhenium heater filaments for the MOCVD Industry. Rhenium Alloys has been the OEM for many of the world’s most reputable and respected MOCVD equipment manufacturers, along with being the specialty filament supplier for the most revolutionary and technology leading LED companies in the world.

Rhenium Alloys produces Rhenium Heater Filaments for today’s most reputable systems, and continues to manufacture rhenium filaments for legacy systems including the D125, D180 and D300 units. OEM and customer specific versions are also being produced daily. Rhenium Alloys can produce rhenium filaments to any customer’s design specifications or thicknesses.

Product Datasheet

Downloads

Proprietary, Patent Pending, Surface Treatment

Rhenium Alloys also offers a proprietary, patent pending, surface treatment which increases the heat transfer efficiency of the filament without adding the risk of contamination from steel shot-peening and other aggressive mechanical operations utilized by our competitors. This allows us to offer the highest purity Rhenium Heater Filament on the market.

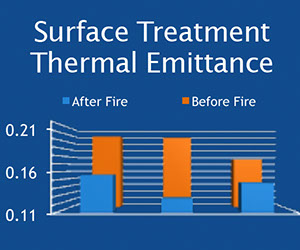

Surface Treatment Thermal Emittance

RAI Re Element with Patent Pending Treatment

- Highest Initial Emittance

- Highest Final Emittance

- Ultra-High Purity Rhenium

- Larger, More Stable Microstructure

- Patent Pending – Zero Contamination Risk Surface Treatment

Rhenium Filament Discounts and Trade-Ins

Rhenium Alloys offers discounts on new rhenium filaments with the trade-in of obsolete or old rhenium filaments.

MOCVD Filament Repair

Rhenium Alloys can also repair minimally damaged filaments on a case by case basis. Although most repairs return the filaments back to original functionality, Rhenium Alloys does not warranty any repaired filaments.

What is MOCVD?

MOCVD stands for Metal Organic Chemical Vapour Deposition, a technique for depositing thin layers of atoms onto a semiconductor wafer. MOCVD allows the build-up of many layers, each of precise thickness, creating a material with specific optical and electrical properties.

Standard Rhenium Heater Filaments by System Type

Rhenium Properties

Atomic Weight:Density: Melting Point:Boiling Point:Coefficient of Linear Thermal Expansion:Specific Heat:Thermal Conductivity: Ultimate Tensile Strength:Yield Strength at 0.2% Offset:Elongation:Hardness:Strain-Hardening Exponent:Shear Modulus:Elastic Modulus:Poissons Ratio:Creep Strength (2200 ᵒC):186.221.04 g/cm³ 3186 °C5627 °C6.8 μm/m·K from 20 to 1000 °C25.7 kJ/kg·K 25 °C71.2 W/m·K at 20 °C 1130 MPa at 20 °C, 81.70 MPa at 2149 °C379 MPa at 20 °C, 77.2 MPa at 2149 °C 24% at 20 °C, 10% at 2149 °C225 VHN as annealed0.52170 GPa at 20 °C460 GPa at 20 °C, 10.3 GPa at 2149 °C0.4910-h rupture stress, 20 MPa; 100-h rupture stress, 10 MpaMechanical PropertiesThermal PropertiesTypical Properties

Fabrication Characteristics and Chemical Properties

- Welding: Electron Beam welding and Laser joining methods produce extremely ductile joints.

- General Resistance to Corrosion: Oxidation in air is catastrophic above 600 ᵒC due to the formation of rhenium heptoxide (Re₂O₇), which has a melting point of 363 ᵒC. Rhenium is resistant to carburization; it withstands arc corrosion well and has good wear resistance.

- Resistance to Specific Agents: Rhenium is resistant to water cycle corrosion; to sulfuric acid and hydrochloric acid (but can be dissolved by nitric acid); to liquid alkali metal corrosion; and to attack by molten zinc, silver, copper, and aluminum.

Made in USA

Our Rhenium MOCVD Heater Filament products are proudly Made in USA.

Website by: Unity Design, Inc. Icon Fonts: Font Awesome

PH: 440-365-7388

FX: 888-366-9830

TF: 888-743-6486

(888-RHENIUM)