Learn more about Rhenium Alloys

Request Quote

Careers – Download Application

TF: 888-RHENIUM PH: 440-365-7388 FX: 888-366-9830

Quality Assurance

Inspection Equipment

Rhenium Alloy’s Quality System

will ensure that you receive your product manufactured to your

exact specifications.

Whitepapers and Abstracts

Resources and Downloads

Rhenium Alloys, Inc. consistently researches and develops new applications for its refractory metal products.

Contact Rhenium Alloys

Request Quote

Careers – Download Application

TF: 888-RHENIUM PH: 440-365-7388 FX: 888-366-9830

Industrial Services

Rhenium Alloys has the expertise and equipment to handle many industrial metal services.

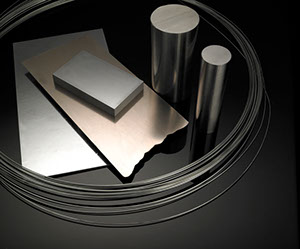

Products & Materials

Molybdenum (Mo)

Softer and more ductile than Tungsten, Molybdenum is a silvery white, very hard transition metal. Discovered in 1778, it was often confused with graphite and lead ore. Molybdenum is a refractory metal. Refractory metals are renowned for their high melting temperatures and low vapor pressures. Molybdenum has a high elastic modulus and one of the highest melting points of all pure elements. Of the more readily available metals, only Tungsten and Tantalum have higher melting points. Molybdenum is attacked slowly by acids. Molybdenum has found application as electrodes for electrically heated glass furnaces and foreheaths, as a filament material in electronic and electrical applications, and is used in nuclear energy applications and for missile and aircraft parts. Molybdenum is also a valuable catalyst in the refining of petroleum. Molybdenum is an essential trace element in plant nutrition.

Softer and more ductile than Tungsten, Molybdenum is a silvery white, very hard transition metal. Discovered in 1778, it was often confused with graphite and lead ore. Molybdenum is a refractory metal. Refractory metals are renowned for their high melting temperatures and low vapor pressures. Molybdenum has a high elastic modulus and one of the highest melting points of all pure elements. Of the more readily available metals, only Tungsten and Tantalum have higher melting points. Molybdenum is attacked slowly by acids. Molybdenum has found application as electrodes for electrically heated glass furnaces and foreheaths, as a filament material in electronic and electrical applications, and is used in nuclear energy applications and for missile and aircraft parts. Molybdenum is also a valuable catalyst in the refining of petroleum. Molybdenum is an essential trace element in plant nutrition.

Product Datasheet

Downloads

Molybdenum Wire

Molybdenum Wire

Rhenium Alloys provides a wide range of wire products to serve applications in major electronics products, thermocouples, high temperature furnace parts, and welding requirements.

Molybdenum wire (moly wire) is more ductile and less dense than Tungsten wire. It is good in high temperature and high pressure applications due to its ability to resist his temperatures without expanding or softening.

Our Rhenium Wire is 99.99% pure and has high strength and excellent ductility. Molybdenum-47.5%-Rhenium Wire is used in welding, electronics and wire mesh grids for the space industries. Tungsten-Rhenium Wire is a staple in thermocouples and electronics products. Tungsten Wire, with its very high tensile strength even at a very small diameter, is widely used for thermocouples, electronic devices, and lighting.

All Wire compositions are available in a full range of sizes (as small as .001”) to meet your requirements.

Molybdenum Flat Wire

One of the few producers in the Americas with this capability, Rhenium Alloys is proud to offer the following flat wire products.

Types of Flat Wire

- Rolled (can be produced as thin as .004" with a standard tolerance of .0004")

- Drawn

- Etched

Secondary Operations

- Etching

- Ultrasonic Cleaning

Molybdenum ROD

Refractory metal Molybdenum rod (bar) products are available in a broad range of sizes (up to 6” in diameter) and customized solutions.

Molybdenum alloys serve a wide range of applications in electronics, furnace, joining, and aerospace industries. Precise alloying of Rhenium with these other refractory metals adds both ductility and strength to suit customer specifications.

Molybdenum Tubing

Molybdenum is a soft, ductile refractory metal that is ideal for thermocouple sheaths, especially when used in very high heat conditions. Molybdenum Tubing is also specified for electrical, electronic, and semiconductor applications. Rhenium Alloys is the world leader in Moly Tubing fabrication.

Molybdenum is a soft, ductile refractory metal that is ideal for thermocouple sheaths, especially when used in very high heat conditions. Molybdenum Tubing is also specified for electrical, electronic, and semiconductor applications. Rhenium Alloys is the world leader in Moly Tubing fabrication.

Molybdenum LX

Moly LX tubing is a Molybdenum Alloy containing Lanthanum oxide. This composition provides extraordinary ductility after exposure to elevated temperatures. Moly LX has finely disbursed particles of Lanthanum Oxide which, when combined with elongated grain structures, leads to excellent high temperature properties. Operational temperatures of 2000°C are achievable and especially with creep properties. All standard tube sizes are available with Moly LX.

Molybdenum LCAC

The low carbon arc cast (LCAC) molybdenum is produced by vacuum arc-casting which is unique to H.C. Starck. This special low-carbon grade is 99.97% pure molybdenum and contains a maximum of .010% residual carbon. In the vacuum arc-casting process, 99.5% pure molybdenum powder is arc-cast in to ingots and then is further processed by extrusion followed by forging or rolling. The LCAC molybdenum is a homogeneous product which has very low residual elements that provides better strength at elevated temperatures and exhibits excellent workability, weld-ability and good machining characteristics.

Molybdenum Electrodes for Metal Disintegrators and Spark Erosion Equipment

Molybdenum (Moly), due to its higher melting point, lower wear, and longer life, is the most recommended material by Metal Disintegrator and Spark Erosion Equipment Manufacturers. Rhenium Alloys is the world leader in Moly Tubing fabrication and offers the highest quality and largest selection of Moly Electrodes available on the market.

*Most Standard sizes are in stock and available for shipment within 2 weeks.

Contact us regarding any specialized applications, sizes or configurations. We specialize in product development and thrive on fulfilling our customer's requirements.

Inch

0.020

0.025

0.030

0.035

0.040

0.050

0.060

0.070

0.075

0.079

0.090

0.098

0.100

0.110

0.115

0.118

0.125

0.140

0.156

0.170

0.175

0.177

0.187

0.200

0.218

0.230

0.236

0.250

0.276

0.285

0.290

0.312

0.342

0.354

0.375

0.393

0.406

0.433

0.437

0.465

0.500

Millimeter

1

1.5

2

2.5

3

3.5

4

4.5

5

5.5

6

7

8

9

10

11

Inch

0.004

0.005

0.006

0.007

0.008

0.010

0.013

0.014

0.015

0.016

0.018

0.020

0.020

0.023

0.025

0.025

0.025

0.027

0.030

0.033

0.035

0.036

0.035

0.041

0.042

0.039

0.042

0.050

0.051

0.043

0.045

0.056

0.063

0.061

0.071

0.072

0.078

0.074

0.076

0.090

0.087

Inch

0.012

0.015

0.018

0.021

0.024

0.030

0.035

0.042

0.045

0.048

0.054

0.059

0.060

0.064

0.065

0.068

0.075

0.086

0.096

0.104

0.105

0.105

0.117

0.118

0.134

0.152

0.152

0.150

0.174

0.199

0.200

0.200

0.216

0.232

0.233

0.249

0.250

0.285

0.285

0.285

0.326

Outside Diameter

Approx. Wall

Approx. Inside Diameter

Moly (Molybdenum) Electrode Size List

CAN BE USED FOR ALL MAKES OF METAL DISINTEGRATORS

Made in USA

Our Molybdenum (Moly) and Molybdenum alloy products are proudly Made in USA.

Molybdenum GENERAL PROPERTIES

Symbol:

Atomic Number:

Atomic Weight:

Density:

Melting Point:

Boiling Point:

Thermal Conductivity:

Electrical Resistivity:

Electronegativity:

Specific Heat:

Heat of Vaporization:

Heat of Fusion:

Modulus of Elasticity:

Thermal Coefficient of Expansion:

Electrical Conductivity:

Mo

42

95.94

10.22 gm/cc

2617 °C

4612 °C

1.38 W/cm/K @ 298.2 K

5.2 microhm-cm @ 0 °C

1.9 Paulings

0.0599 Cal/g/K @ 25 °C

128 K-Cal/gm atom at 4612 °C

6.6 Cal/gm mole

32 x 1010 Pa @ 25 °C

5 x 10-6 cm/cm @ 25 °C

34% I.A.C.S.

Website by: Unity Design, Inc. Icon Fonts: Font Awesome

PH: 440-365-7388

FX: 888-366-9830

TF: 888-743-6486

(888-RHENIUM)